Product series description VACUCELL

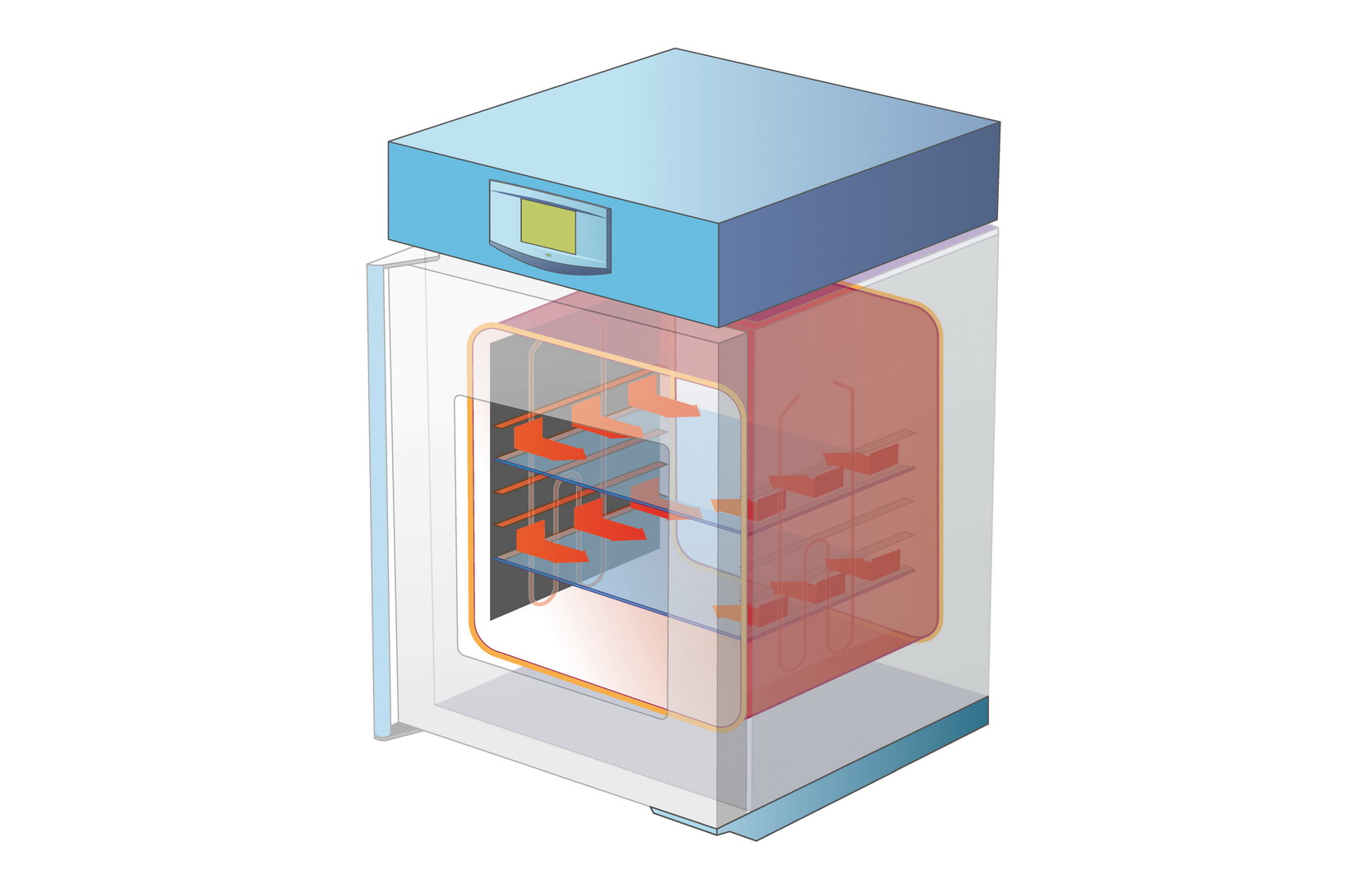

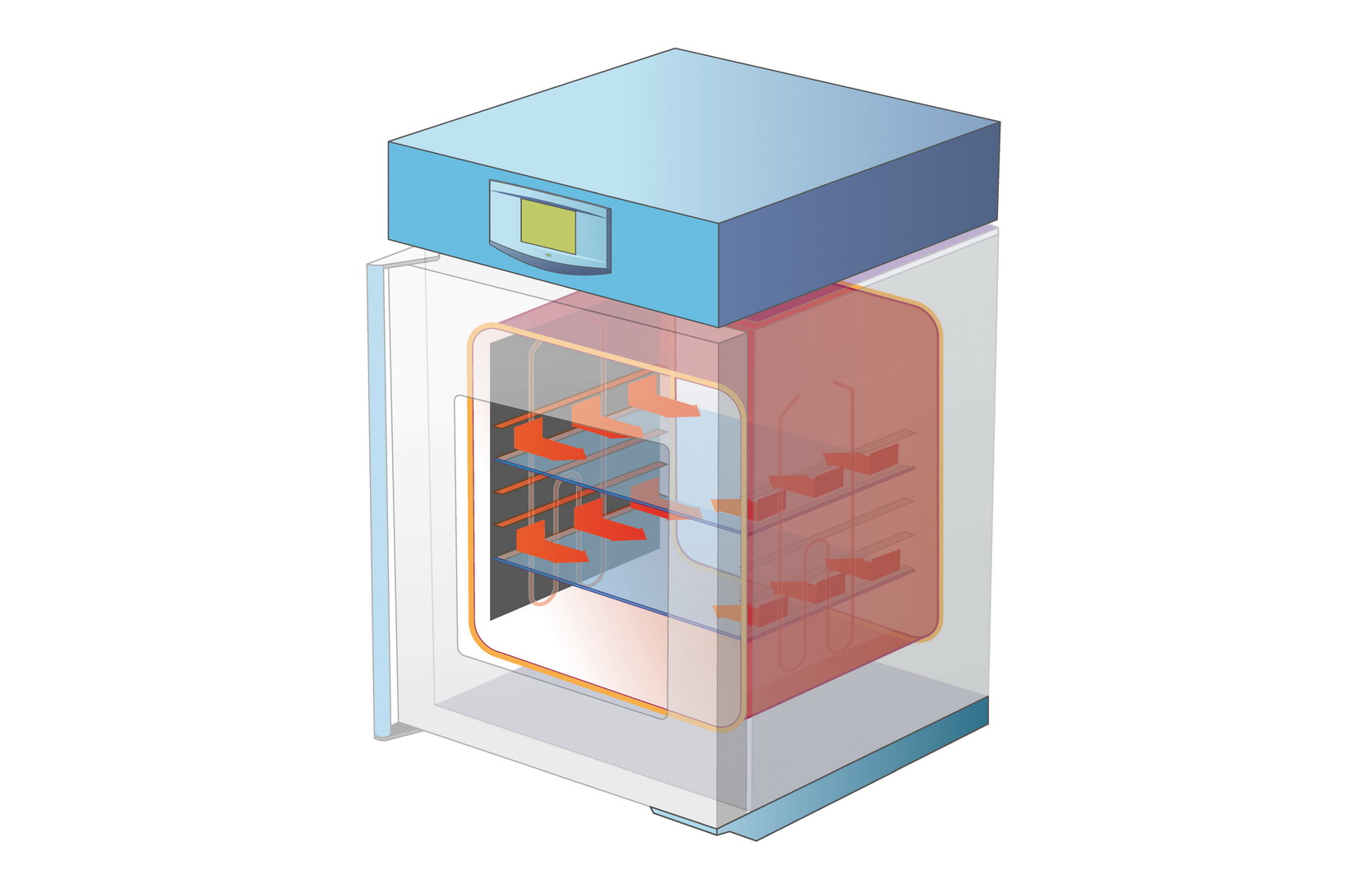

Heat Propagation in Vacuum or Inert Gas

The principle of operation is based on the principle of drying in vacuum with the possibility of air displacement in the chamber by an inert gas. The direct heated stainless steel chamber of the device allows precise heating and drying of samples up to constant weight. Standard equipment includes a bushing with a diameter of 40 mm, input for inert gas connection and a needle valve for fine dosing. For the case of inner overpressure, the device is equipped with a large-area door overpressure valve “Ventiflex”.

Product Series Description

The series VACUCELL® is suitable for perfect drying of thermolabile and oxidation-sensitive materials, complicated components, for drying of samples up to a constant mass etc. in vacuum. These devices are suitable for plastic processing, in electrical engineering, chemical and pharmaceutical industry. The series VACUCELL® is characterized by noiseless run and soft heating of samples in the chamber and offers high-quality and save heating and drying of samples up to a constant mass. Therefore it is suitable for perfect and safe tempering and drying not only of thermolabile, oxidation-sensitive or powder-like materials in laboratories, but also of complicated articles with many holes and threads in industry. The series VACUCELL® offers high operation comfort and precise control and therefore it is suitable for demanding and precise tests and processes. The devices VACUCELL® can be, on request, completed by the box “Vacustation” without or inclusive the selected type of vacuum pump. The devices VACUCELL® meet requirements of technical-legislative regulations in CZ and EU.

Basic Design Components

Self-supporting outer jacket made of galvanized steel sheet with hard and resistant baking varnish on the outer side. The inner single-jacket chamber with shelves is made of thick-wall stainless steel (DIN 1.4571, AISI 316 Ti). The door panel is made of large-area safety glass with a plastic foil, that enables to monitor processes in the chamber and serves as a large-area overpressure valve. For the purpose of energy saving and minimizing the heat radiated to the ambient air the chamber is perfectly insulated with an ecological insulating material. The inner walls of the chamber can be easily removed without using any tool, e.g. for the purpose of cleaning. On top of that the chamber has a continuously adjustable air flap and inner glass door. The door is secured at four points for perfect tightening. The standard equipment consists of integrated duct with the diameter of 40 mm, inert gas connection and needle valve.

Changes in the design and make reserved.

VACUCELL 22 - ECO line

VACUCELL 22 - ECO line  VACUCELL 55 - ECO line

VACUCELL 55 - ECO line  VACUCELL 111 - ECO line

VACUCELL 111 - ECO line  VACUCELL 22 - EVO line

VACUCELL 22 - EVO line  VACUCELL 55 - EVO line

VACUCELL 55 - EVO line  VACUCELL 111 - EVO line

VACUCELL 111 - EVO line