Product series description DUROCELL

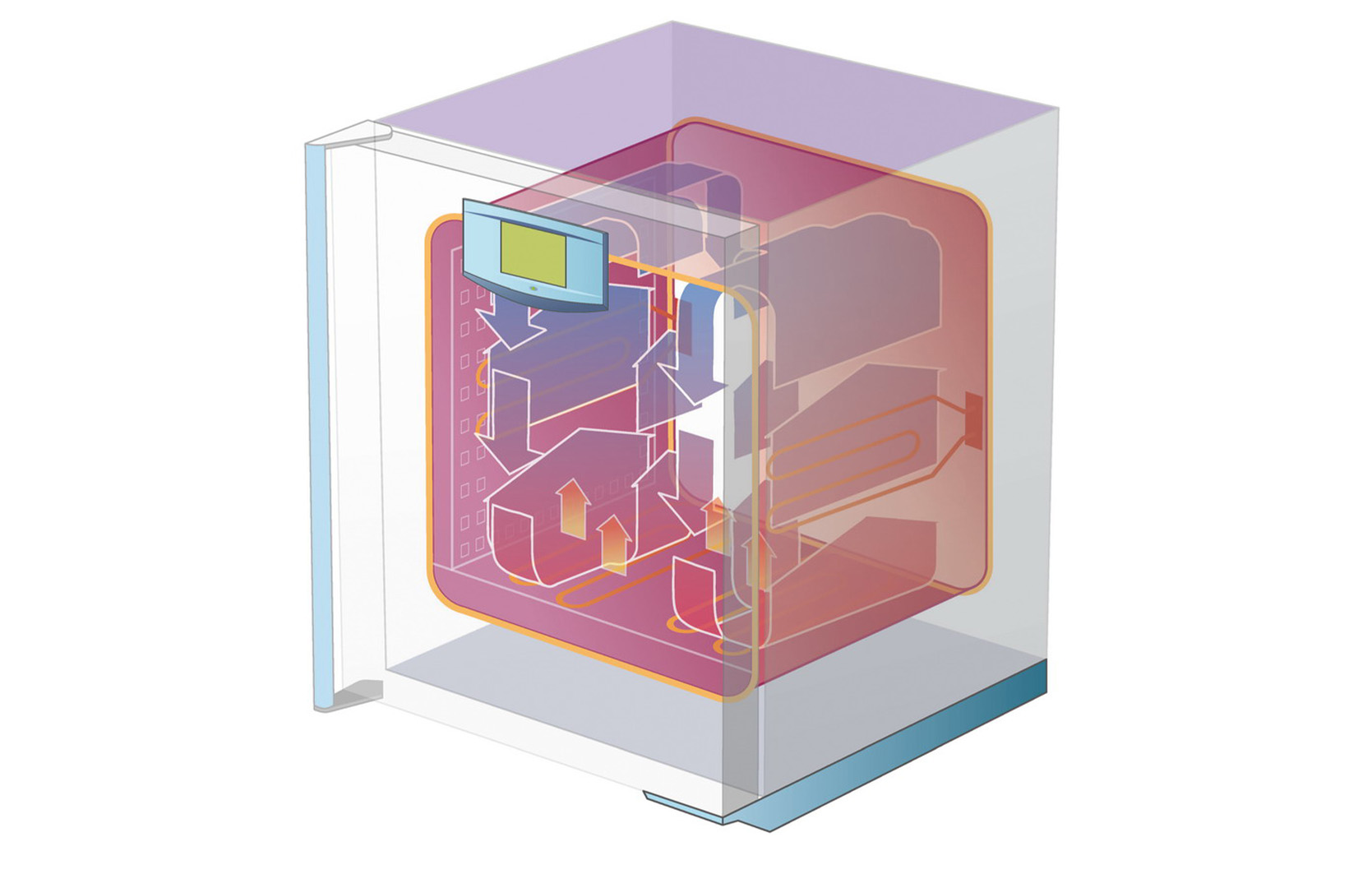

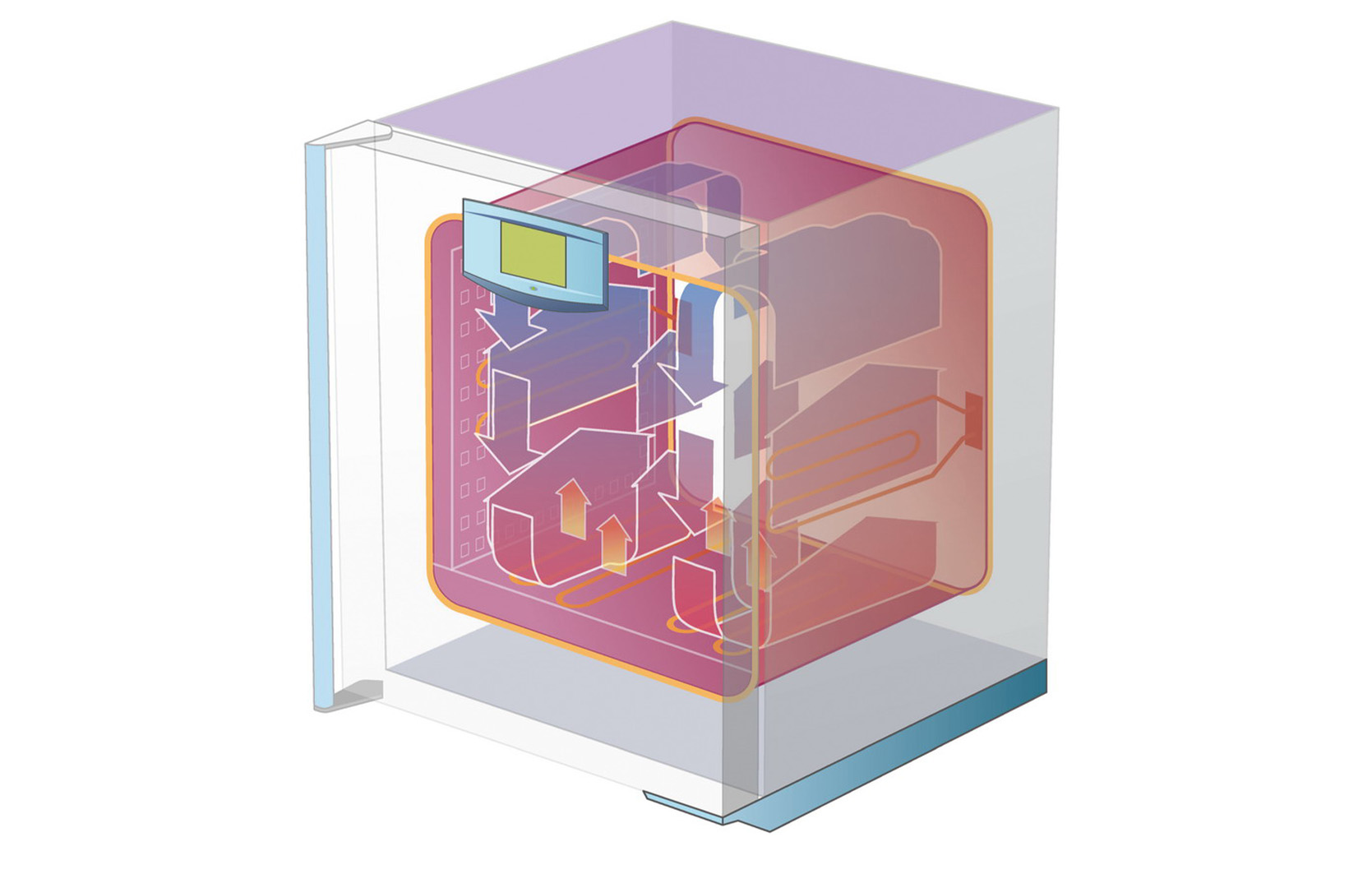

Natural Forced Circulation in the Chamber

The principle of operation is based on fine gravitation air flow in electrically heated chamber of the device.

The double-tube construction of the chamber together with control automatics arrange homogenous distribution of temperature in the chamber, exact progress of processes and short recovery times (return to selected temperature) after the door opening. It is characterised by its economic operation. It is suitable for simple process of drying and heating of standard materials. The devices work on no-noise basis.

Product Series Description

A special line DUROCELL with a highly resistant coating of EPOLON that protects the inner stainless steel surfaces from aggressive agents, such as acids and liquors. These units enable an optimal tempering of materials. They are ideal for acid and basic hydrolysis, extraction through incombustible substances and decomposition of substances at a solid phase. The devices DUROCELL meet requirements of technical-legislative regulations both in CZ and EU.

Basic Design Components

Sturdy design and perfect corrosion prevention are ensured by a self-supporting outer jacket made of galvanized steel sheet with hard and resistant baking varnish on the outer side. The inner double-jacket chamber and the door panel are made of high-quality stainless steel (DIN 1.4301, AISI 304). Inner walls and the door panel are provided with a highly resistant Epolon-coating for higher protection. For the purpose of energy saving and minimizing the heat radiated to the ambient air the chamber is perfectly insulated with an ecological insulating material. The inner walls of the chamber can be easily removed without using any tool, e.g. for the purpose of cleaning. On top of that the chamber has a continuously adjustable air flap and can be provided with a door with window and an interior lighting on request. The door is secured at four points for perfect tightening.

Changes in the design and make reserved.

DUROCELL 22 - ECO line

DUROCELL 22 - ECO line  DUROCELL 55 - ECO line

DUROCELL 55 - ECO line  DUROCELL 111 - ECO line

DUROCELL 111 - ECO line  DUROCELL 222 - ECO line

DUROCELL 222 - ECO line